Your solar investment faces its biggest threat from inverter failures. These account for 43% of all solar system failures and 36% of lost energy production. Most people worry about their panels wearing out, but the inverter proves to be the weak link—even under perfect sunny conditions.

The numbers tell a troubling story about solar inverter reliability. String inverters break down at a rate of 0.89% within their first two years. Solar panel inverters only last 1-20 years, while panels keep working for 25+ years or more. This lifespan gap can reduce your long-term ROI by up to 10%. The maintenance challenges stay the same for all system owners, whether they use a solis inverter, growatt inverter, or any other power inverter type. But you can protect your investment and make your inverter last longer by watching for warning signs and taking preventive steps.

Why Inverter Failures Are the Silent Killer of Solar Systems

Your solar power system’s beating heart – the solar inverter – is also its most vulnerable part. Studies show that inverter failures account for 17% of total incidents in solar PV farms [1]. This makes them a weak link in system reliability. Solar panels quietly generate electricity for decades, but inverters need much more attention throughout your system’s life.

Understanding the role of a solar inverter

Solar inverters do the significant job of converting direct current (DC) electricity from solar panels into alternating current (AC) that powers homes and businesses. They work as the technical brain of your solar PV system [2]. The energy from sunshine stays unusable for standard appliances and the electrical grid without this conversion.

Solar inverters do much more than just convert power:

- They maximise energy harvest through Maximum Power Point Tracking (MPPT)

- They keep your system safe through isolation protection

- They regulate voltage and frequency for grid compatibility

- They monitor performance and detect faults

These inverters come with anti-islanding protection that shuts off during power outages. This prevents electricity from flowing back into the grid and protects utility workers [2]. The inverter’s complex responsibilities mean it has many more electrical components than solar panels. This makes them more likely to fail [3].

Why inverters fail more often than panels

Panels and converters have a substantial reliability gap. String inverters typically last 10-15 years while microinverters can work for 20-25 years [3]. Solar panels, however, often keep working effectively for 25-30 years [2]. A large study found that 34.3% of residential inverters had their first failures within 15 years of operation [4].

Here’s what causes this difference:

Component vulnerability: Electrolytic capacitors inside converters tend to fail first. These parts age faster than dry components and react strongly to temperature changes [5]. The insulated-gate bipolar transistors (IGBTs) and metal-oxide-semiconductor field-effect transistors (MOSFETs) also fail when exposed to high voltage, current, or extreme temperatures [1].

Environmental stressors: Heat and humidity are an inverter’s worst enemies. They struggle most in areas with temperatures above 14°C and 55% humidity. These conditions lead to overheating, moisture getting in, and condensation [1]. Many inverters have trouble handling temperature changes in ground installations, even though they’re rated for outdoor use [1].

Operational strain: Your inverter never stops working. It manages varying loads, voltage changes, and grid connections constantly. This ongoing electrical stress wears components down quickly. Most PV plants need to replace their converters because of limited warranties and high failure rates [6].

Design and manufacturing issues: Electronic components often age too quickly because of design flaws [1]. Manufacturers know about these reliability challenges, but cost pressures often force them to use lower-quality components.

These failures hit your wallet hard. Studies show that converter failures can reduce efficiency by 2.55% to 14.67% [6]. This directly cuts into your system’s output. Research also shows that inverter reliability problems can lower the long-term ROI of residential solar PV systems by up to 10% [1].

String inverters fail at about 0.89% within their first two years. Microinverters do better with only 0.0551% failing [7]. All the same, when string inverters fail, they affect your entire array instead of just one panel.

Inverter failures waste time and money. Industry data shows that major converters problems cause about 80 days of downtime [1]. Your solar investment sits unused during perfect sunny days, eating away at your expected returns.

These vulnerabilities don’t mean solar investments are bad. They just express why you need quality components, proper installation, and regular maintenance. We’ll look at these topics more closely in upcoming sections.

The Most Common Solar Inverter Failures Explained

Solar inverter failures can get pricey and cause unwanted downtime. Your system reacts differently to each type of failure. Let’s look at the warning signs and how to fix these problems.

EEPROM and firmware issues

EEPROM (Electrically Erasable Programmable Read-Only Memory) failures happen when your inverter’s operational firmware and settings memory stops working properly. This essential component keeps your operational data safe even without power.

Common causes of EEPROM failures include:

- Power surges that damage memory integrity

- Data retention problems from ageing components

- Write cycle interruptions due to poor power quality

- Compatibility problems with outdated firmware versions

Your solar inverter might reset to factory settings or show error code 18×86 (single phase) or 8×58 (three phase) during an EEPROM failure. This affects your daily production data but not the energy you’ve already generated. A manual reset usually fixes the issue. Repeated EEPROM failures could point to deeper system issues or problems with grid power quality.

Software glitches show up as operational problems. Modern converters depend heavily on software. Outdated firmware or bugs can cause errors and disrupt operations. Regular software updates help prevent many inverter issues.

GFCI and isolation faults

Ground Fault Circuit Interrupter (GFCI) systems keep your solar inverter safe. These protective circuits watch for excess residual current. They shut down the system when leakage becomes dangerous.

Your converters must separate DC current from solar panels and AC current that powers your home or grid. This separation keeps the system safe and running well. Problems here lead to isolation faults.

GFCI failures usually come from:

- Electrical parts damaged by moisture

- Design limits exceeded by electrical overloads

- Poor protection against lightning

- Protection limits exceeded by leakage current

Single-phase inverters with isolation resistance below 600kΩ or three-phase inverters below 1MΩ trigger isolation errors. These problems create serious safety risks beyond just hurting performance. They could cause electrical fires or shocks.

The best way to fix these issues is to check ground connections, AC wiring, and surge protectors. Morning moisture often causes temporary isolation faults. Check the system right after these faults happen for best results.

Relay and overload problems

Relays often fail in solar inverters. These parts protect the grid by isolating it from the inverter’s main circuit during faults. Modern converters need relays to control electrical circuits and manage power flow.

Relays typically fail because of:

- Contact wear from constant switching

- Overheating or voltage spikes damaging coils

- Ground shorts in AC-side phase lines

- Systems needing restarts due to false errors

Overload happens when inverters handle too much power. This damages parts and triggers safety shutdowns. Many converters warn you before shutting down completely, giving you time to reduce power loads.

You can find relay problems by measuring phase-to-ground voltage. Readings under 100V usually mean phase wires have shorted to ground. This needs new cables or rewiring.

Grid lost faults and their impact

Grid lost faults stop energy production when your converters can’t detect AC voltage or finds it too low. These problems do more than just trigger error codes – they completely stop power generation until fixed.

These faults usually happen because of:

- Local power outages

- Disconnected wiring between inverter and grid

- Undersized parts tripping circuit breakers

- Voltage protectors disconnecting

- Bad AC connections causing spotty contact

Grid lost faults cost more than just repairs. Every day without power means lost generation and less return on investment. A typical 10kW system loses significant revenue even after a few days offline.

Check these issues with a multimeter to measure AC output voltage (usually 220-240V for homes). Start at the inverter and work toward your main breaker. Loose connections and wrong-sized circuit breakers often cause problems even when everything else works fine.

How Inverter Failures Drain Your Solar Investment

Your solar system’s performance can take a nosedive due to inverter failures, causing a hidden financial drain. Research shows that inverter problems cause up to 60% of total failures in solar farms and can slash production by 30% [8]. These technical issues slowly eat away at your returns without any clear warning signs.

Downtime losses: kWh lost and revenue effect

Each day of inverter inactivity means money down the drain. The National Renewable Energy Laboratory’s research proves that converter failures caused 36% of energy losses in a 27-month study. Module failures only resulted in 5% of these losses [9]. These numbers show why your system’s financial success depends on converter reliability.

A faulty inverter can cut your system’s lifetime return on investment by 10% [10]. This happens in two ways: you lose production chances and your system runs inefficiently.

System size determines the losses:

- Small home systems (5-10kW) lose about £8.25/kWp in yearly production value [8]

- Commercial systems lose more, sometimes exceeding £38/kWp yearly [8]

- Large 100MW plants with ongoing inverter problems could lose £3 million each year [8]

String inverter failures shut down entire arrays at once. The average repair time after a major breakdown is 80 days [11]. This means you lose a quarter of your yearly production even during perfect weather.

Service and replacement costs for a 10kW system

Inverter maintenance and replacement add another layer of costs beyond lost production. You’ll need to replace most solar panel inverters every 10-15 years [12]. Your panels, however, will keep working well for 25+ years.

A typical 10kW system’s converters costs break down like this:

Replacement costs: New inverters cost between £500-£2,000 based on quality and specs [12]. Total replacement, including installation, runs about £2,382 [13].

Maintenance expenses: Annual inverter service costs £133 [10]. People often forget this cost when calculating initial returns.

Emergency repair premiums: Unexpected repairs can push your O&M costs up by 23% [8]. This happens especially with emergency or weekend calls.

Warranty coverage rarely includes system downtime, shipping, or reinstallation costs [10]. This means you’ll still pay significant hidden costs even with “free” warranty replacements.

Multiple replacement cycles show the true financial picture. The worst case – inverter failures every five years after warranty ends – can drop your system’s ROI from 2.2 to 1.95 [10]. This reduction questions your solar investment’s value.

Regular maintenance is your best bet to protect your investment. Studies show that good reliability practises can cut inverter-related failures by 40-80% [8]. This could save you thousands over your system’s life.

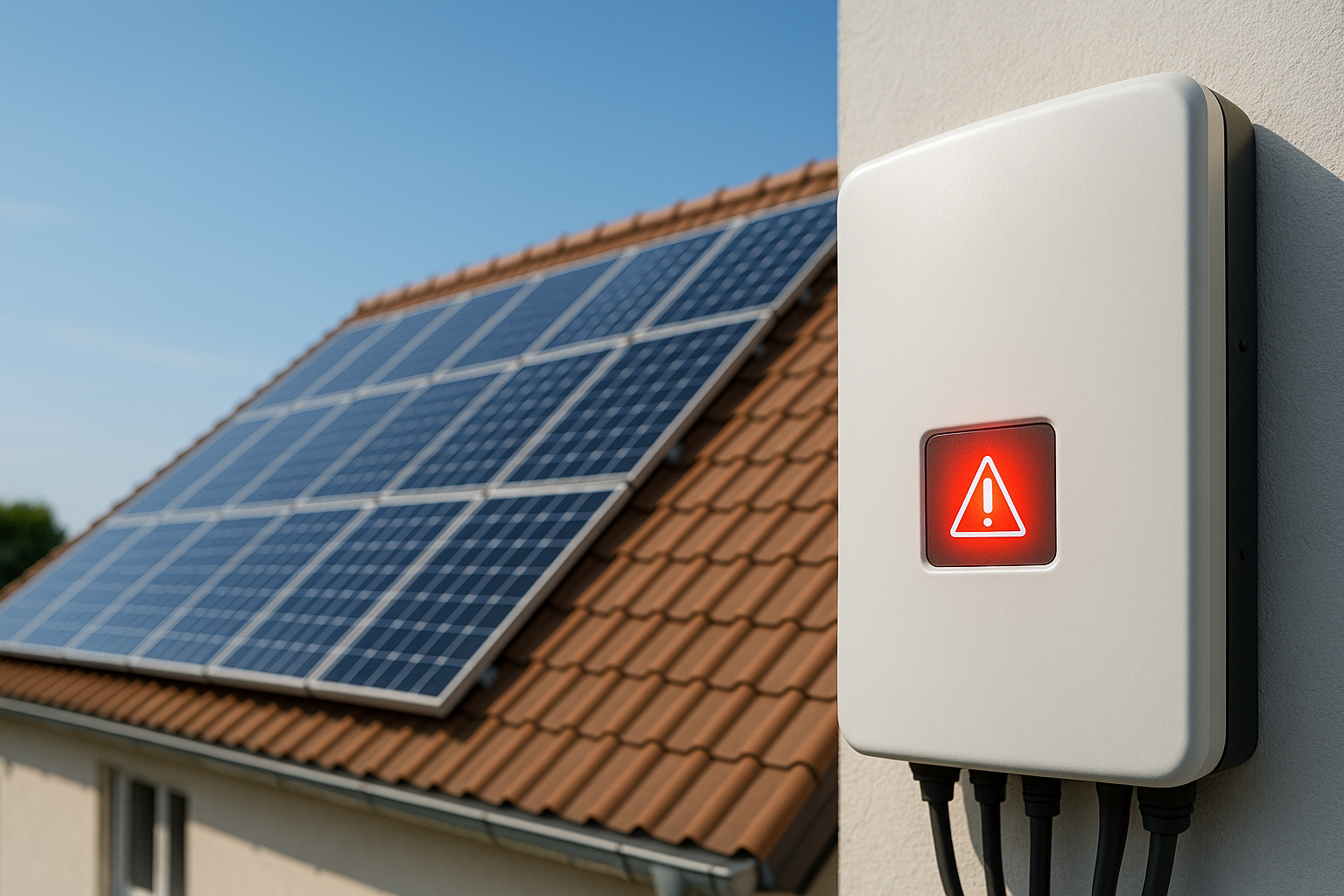

Early Warning Signs You Should Never Ignore

Your solar inverter can give you early warning signs of trouble, just like a car does before breaking down. Spotting these signs early could save you thousands in repair costs and lost energy production.

Temperature drift and overheating

Heat is your solar inverter’s biggest enemy when it comes to electronic components. Research shows that electronic component failures follow the Arrhenius equation, which means their lifespan halves for each 10°C rise in temperature [2]. This is a big deal as it means that overheating inverters break down nowhere near as often as those working at the right temperatures.

Your inverter has a smart protection system called “temperature derating” that kicks in when it gets too hot. The inverter reduces its power output to avoid internal damage during this process [2]. While this keeps your equipment safe, it also cuts down energy production right when you need it most—usually during hot weather when air conditioning is in high demand.

You should check your inverter’s surface temperature by touching its casing. A well-functioning inverter feels warm but not too hot [14]. This simple test reveals vital diagnostic information because temperature changes from normal operation often show up before major parts fail.

Here are some temperature standards to watch for:

- Temperatures above 25°C lead to power losses of 0.5% per 1°C increase [3]

- Most inverters start derating at about 45-50°C [5]

- Surface temperatures you can’t touch comfortably point to possible problems [2]

Proper airflow is vital in managing temperature. Poor ventilation, dust buildup on cooling parts, or placing the inverter in direct sunlight can all lead to early failure [15].

Voltage fluctuations and fan anomalies

Changes in voltage often point to developing problems in your solar system. Your inverter might have voltage stability issues if you see uneven energy production during steady weather conditions [14]. These changes can happen because of:

- Uneven loads across your electrical system

- Changes in power use throughout the day

- Irregular power generation from panels

- Grid instability affecting inverter operation [16]

Most inverters use reactive power control to steady these fluctuations [16]. Any unexplained instability usually means parts are wearing down and need attention.

Fan problems are another warning sign you can easily spot. Strange buzzing or cooling fans that don’t work usually spell trouble [17]. Well-maintained cooling fans last about 40,000 hours [2].

Watch out for these fan warning signs:

- Grinding or buzzing noises during operation

- Fans running at odd speeds or stopping randomly

- Fans not moving even in high temperatures

Fan problems usually come from:

- Objects stuck in fan blades

- Not enough space around the unit (normal spacing 0.5m)

- Blocked cooling ducts

- Loose screws that cause vibration [18]

Time to sound alarms and get help

Some warning signs mean you need professional help right away. Call for service if you see:

- Error messages or warning lights on the display [17]

- Sparks, smoke, or odd smells from the inverter [7]

- Regular shutdowns in normal conditions [17]

- Surface too hot to touch [2]

- Power production drops of 5% or more [14]

Network connection rules usually ask for professional checks every five years [2]. In spite of that, checking things yourself each month can catch problems early. Make it a habit to check display readings, listen for odd sounds, and monitor temperatures.

Prevention costs less than emergency fixes. Simple solutions like shade covers can drop wall temperatures by up to 10°C, which helps your inverter last longer [3]. Good airflow, updated firmware, and regular professional checks can prevent many common failures.

These warning signs are your inverter’s way of telling you something’s wrong before it completely breaks down. Quick responses to these signals protect both your equipment and your investment in renewable energy for years ahead.

Proven Ways to Prevent Inverter Failures

Solar inverter maintenance will save you money and prevent future problems. Research shows that using reliability-focused best practises can cut inverter failures by 40-80% [4]. This protects your solar investment for many years.

Choosing the right installation location

Your solar inverter’s placement will affect how long it lasts. Never put an inverter in direct sunlight because it will overheat and become less efficient [19]. The ideal spot is a shaded area that stays dry and protects your system.

Here are the key installation guidelines you should follow:

- Mount the inverter vertically with connections pointing downward [19]

- Leave at least 6 inches of space on all sides so heat can escape [20]

- Put it at eye level between 500mm-2m from the ground for easy monitoring [20]

- Pick a spot with good airflow like a garage, shed, or covered outdoor wall [19]

High temperatures are tough on inverters. Every 10°C increase cuts your component’s lifespan in half [19]. Good airflow is vital to keep your inverter working at its best.

Keeping firmware updated and logs active

Your inverter needs regular software updates just like your phone. New firmware helps your inverter run efficiently and gives you better security and performance [6].

Updated firmware brings real benefits:

- Better energy output through smarter algorithms [6]

- More safety features that protect against faults [6]

- Better reliability through fixed bugs and improved performance [6]

Active system logs help spot problems early. This lets you fix issues before they cause expensive breakdowns [1].

Routine maintenance and inspections

Set up a monthly schedule to check for loose connections. These can cause electrical arcing and too much heat [1]. Check the cooling fans every three months to make sure they’re not blocked [1].

You should get a professional technician for detailed yearly inspections. They’ll check internal parts and adjust system settings [21]. Any warning codes need quick attention to prevent serious damage [1].

Spare parts strategy: shadow inverter concept

Bigger installations or critical systems should use a shadow inverter strategy. Having spare parts or a backup inverter ready can cut downtime from 80 days to just hours [22].

Even home systems benefit from knowing which parts fail most in your inverter model. Replacing these parts before they break down has proven to prevent long periods of downtime [23].

The Future of Solar Inverters: Smarter, Stronger, Safer

Solar inverter technology is advancing faster than ever, going well beyond basic reliability fixes. Advanced technology reshaping the market shows us a future where inverters not only last longer but revolutionise how solar systems work.

Silicon carbide (SiC) power devices

Silicon carbide technology marks a breakthrough for solar inverters and performs better than traditional silicon components. This wide bandgap semiconductor material lets inverters work at higher voltage, temperature, and frequency ranges than conventional silicon devices [24].

Key advantages of SiC include:

- Up to 30% lower power losses compared to traditional inverters [24]

- Increased power density by approximately 50% [24]

- System cost savings of up to 10% through reduced cooling requirements [24]

- Better heat dissipation and thermal performance [25]

SiC-powered inverters reach efficiency levels up to 99% [26], which helps you get more energy. These inverters also manage to keep optimal performance even in tough environmental conditions, thanks to their improved thermal stability [27].

AI-driven diagnostics and predictive maintenance

AI is changing how we monitor and maintain solar inverters. Machine learning algorithms analyse inverter error logs and operational data to spot potential failures early [28].

Real-world applications show impressive results. A case study showed that automation cut analysis time from 358 hours to just 3 hours [29], which means faster responses to emerging issues. About 77% of companies plan to switch to predictive maintenance soon, seeing AI as the driving force behind this development [28].

The systems create baseline performance patterns and then spot subtle changes that might signal upcoming problems. When issues are caught early, maintenance teams can fix them proactively, which cuts down system downtime and costs [30].

Modular inverter designs for easy upgrades

Modular inverter design stands out as another big step forward in solar technology. These systems come with plug-and-play components that make maintenance 70% faster [31].

Sungrow’s 1+X modular inverter shows this approach in action. It can be configured up to 8.8MW with 1.1MW modular capacity [31]. Each unit works on its own, so if one unit has issues, the others keep working—this means more energy output even during repairs.

The benefits of modular systems go beyond easy maintenance. Users can expand their systems as energy needs grow [32]. The systems adapt better to tough environments with IP65 ingress protection levels [31] and work well with battery storage systems without extra modifications [31].

These improvements show how solar inverters are becoming smarter, stronger, and more reliable. What was once the weakest part of solar systems has become a sophisticated energy management hub.

Final Thoughts

Your solar system’s inverters are its heart, yet they remain the most vulnerable component that silently drains your investment when they fail. These hidden costs should prompt action—not alarm. In fact, your inverter can deliver reliable performance throughout its operational life with proper care and attention.

Temperature monitoring, regular visual inspections, and quick responses to warning signs could save thousands in repair costs and lost energy production. Smart maintenance decisions like picking the right installation spots and keeping firmware updated will extend your inverter’s lifespan by a lot.

Solar inverter technology’s future looks promising. Silicon carbide power devices, AI-driven diagnostics, and modular designs will end up changing today’s weak link into tomorrow’s intelligent energy hub. In spite of that, these advancements can’t replace careful maintenance practises.

Your solar investment needs protection. So, the preventative strategies outlined in this piece should become standard practise for every system owner. A proactive approach costs nowhere near as much as reactive repairs—both financially and in terms of system downtime.

Schedule your next inverter inspection today. Set up a regular maintenance routine and track performance consistently. These simple steps could double your inverter’s effective lifespan and protect your renewable energy investment for decades.

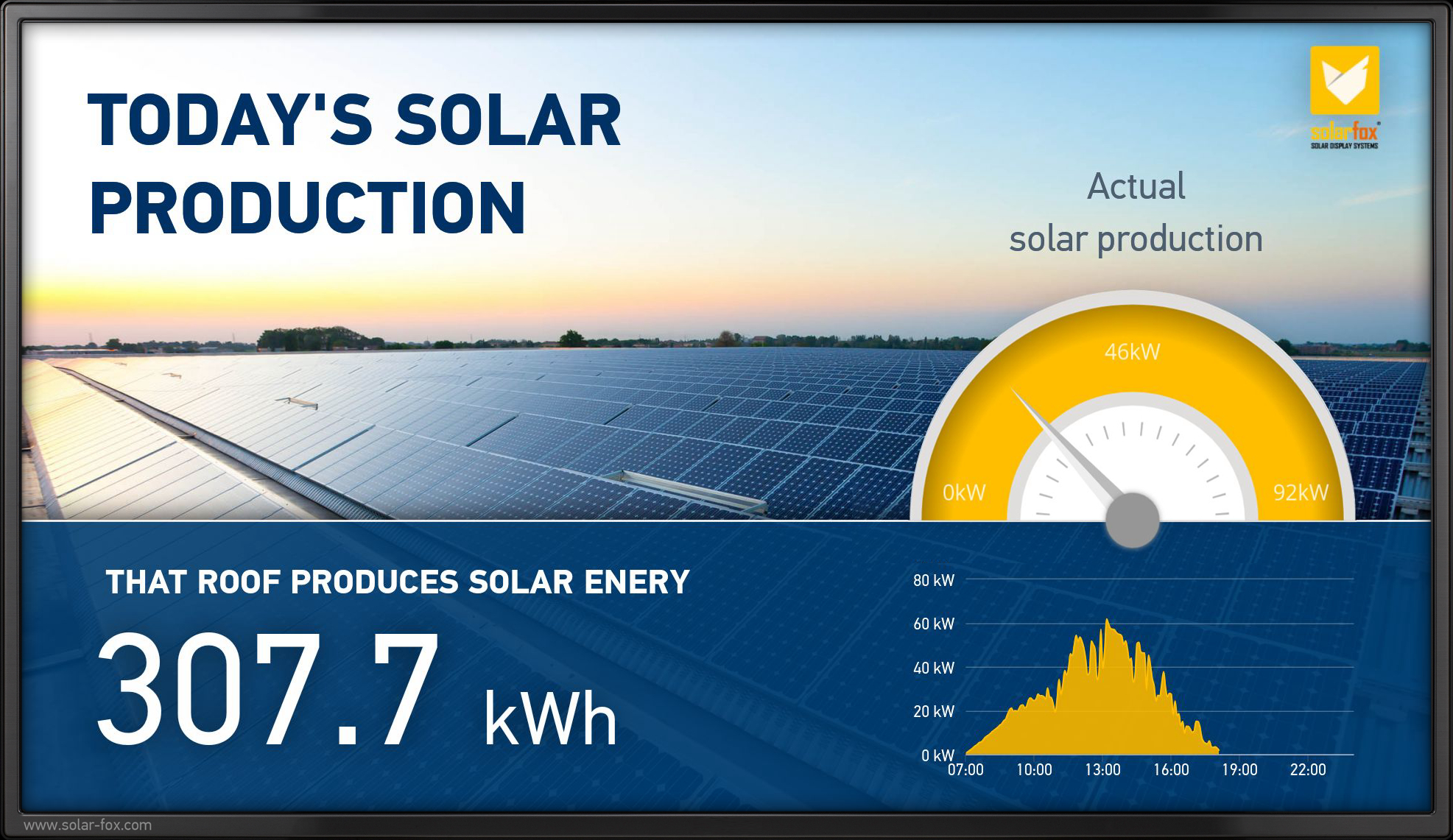

For comprehensive monitoring of your PV system, integrating advanced datalogger systems provides crucial real-time oversight and rapid problem detection. Systems like VCOM Cloud from Meteocontrol, it’s blue’Log X-Series dataloggers offer professional monitoring solutions that immediately identify inverter malfunctions, preventing prolonged performance issues and revenue loss. Similarly, Solar-Log™ monitoring platforms excel at detecting faults such as inverter failures before they become permanent problems, with the system comparing inverter performance to quickly spot deviations down to the MPP tracker level. To effectively communicate system status and potential issues throughout commercial buildings, Solarfox® displays provide an innovative visualization solution that transforms complex PV data into easily understandable graphics for building occupants and visitors, making solar power system performance—and any problems—immediately visible to all stakeholders.

FAQs

Q1. How often do solar inverters typically fail? Solar inverter failure rates vary, but studies show that about 34% of residential converters experience their first failure within 15 years of operation. String inverters have a failure rate of approximately 0.89% within the first two years, while microinverters have a much lower rate of about 0.0551%.

Q2. What are the financial implications of inverter failures? Inverter failures can significantly impact your solar investment. They can reduce the long-term ROI of residential solar PV systems by up to 10%. For a 10kW system, annual production value losses can be around £82.50, with replacement costs ranging from £500 to £2,000 depending on the converters specifications.

Q3. What are some early warning signs of inverter problems? Key warning signs include unusual temperature increases, voltage fluctuations, and fan anomalies. If your inverter feels excessively hot to touch, produces inconsistent energy despite consistent weather, or you hear abnormal buzzing noises from the cooling fans, these could indicate developing issues requiring attention.

Q4. How can I prevent inverter failures? To prevent failures, ensure proper installation in a well-ventilated area away from direct sunlight, keep firmware updated, conduct regular maintenance and inspections, and consider implementing a spare parts strategy. These measures can reduce converter-related failures by 40-80%.

Q5. What advancements are being made in solar inverter technology? Future solar converters are becoming smarter and more reliable. Innovations include silicon carbide (SiC) power devices offering up to 30% lower power losses, AI-driven diagnostics for predictive maintenance, and modular designs allowing for easier upgrades and maintenance, potentially improving efficiency and lifespan.

References

[1] – https://en.growatt.com/media/blogs/solar-inverter-maintenance-checklist:-7-tips-to-extend-inverters-lifespan

[2] – https://www.solarquotes.com.au/blog/solar-inverter-too-hot/

[3] – https://renewcosolar.com.au/what-happens-when-your-solar-inverter-overheats/

[4] – https://blog.se.com/infrastructure-and-grid/infrastructure-management/2022/10/10/4-ways-to-create-a-resilient-electrical-spare-parts-management-strategy/

[5] – https://www.greentechrenewables.com/article/how-does-heat-affect-solar-inverters

[6] – https://solar-fix.com.au/blog/inverter-firemware-updates/

[7] – https://www.greenlancer.com/post/solar-inverter-repair

[8] – https://www.linkedin.com/pulse/uncovering-true-cost-inverter-failures-solar-power-ignacio-8lynf

[9] – https://www.pvel.com/inverter-testing-to-mitigate-revenue-risk-in-solar-projects/

[10] – https://www.researchgate.net/publication/319888103_The_Effect_of_Inverter_Failures_on_the_Return_on_Investment_of_Solar_Photovoltaic_Systems

[11] – https://kb.solargis.com/docs/energy-system-statistics-losses-and-long-term-degradation

[12] – https://www.greenmatch.co.uk/solar-energy/inverter-replacement

[13] – https://1komma5.com/au/solar/how-much-does-it-cost-to-replace-a-solar-inverter/

[14] – https://makenergy.com/signs-your-solar-inverter-needs-replacement/

[15] – https://fielda.com/blogs/solar-inverter-maintenance-repair-and-service-guide/

[16] – https://www.foxtechsolar.com/a-news-why-solar-inverters-help-mitigate-voltage-fluctuations-and-instabilities

[17] – https://www.greenlancer.com/post/solar-inverter-problems-and-solutions

[18] – https://www.solisinverters.com/global/documentation/Troubleshooting_Guide_Abnormal_Noise_from_Inverter_Causes_and_Solutions_10261833.html

[19] – https://my.sma-service.com/s/article/What-is-The-Best-Spot-to-Place-an-Inverter-in-a-PV-Plant?

[20] – https://www.evergreenelectrical.com.au/blog/location-for-inverter

[21] – https://techfinepv.com/tips-of-solar-inverter-maintenance/

[22] – https://www.sciencedirect.com/science/article/abs/pii/S2213138822007779

[23] – https://www.res-group.com/us/resources/blog/smarter-management-of-solar-assets-for-maximum-performance/

[24] – https://www.wolfspeed.com/applications/power/renewable-energy/solar-energy-systems/

[25] – https://www.arrow.com/en/research-and-events/articles/sic-technology-and-solar-inverter-systems

[26] – https://www.bvrenergy.com.au/blog/innovations-in-solar-inverter-technology-2024-inverter-guide

[27] – https://semiq.com/silicon-carbide-for-solar-energy/

[28] – https://www.solarpowerworldonline.com/2025/04/how-predictive-maintenance-is-transforming-solar-operations-in-the-age-of-ai/

[29] – https://smarthelio.com/from-hours-to-minutes-how-ai-is-revolutionising-solar-plant-diagnostics/

[30] – https://www.moserbaersolar.com/maintenance-and-performance-optimisation/smart-solar-how-ai-powered-predictive-maintenance-is-revolutionising-pv-system-performance/

[31] – https://en.sungrowpower.com/upload/file/20220718/1+X Modular Inverter White Paper.pdf

[32] – https://solarpowernation.com.au/the-future-of-inverter-technology-innovations-and-trends/